Types of Port Cranes

Cranes are believed to have been in use as early as 3000 BCE. The earliest of them, called ‘shadoof’, were used to lift water from lakes and rivers for irrigating farmlands in Egypt. It consisted of a pole with a bucket on one end that was counterbalanced on a fixed support.

The Simple Crane

In its simplest form, a crane consists of a lever and a pulley.

Cranes at a fixed angle, with a single arm, were used in the early days to lift heavy loads. These days, modern cranes that can work from a few degrees angle to a nearly perpendicular position that can lift very heavy loads can be found everywhere, from construction sites to warehouses to seaports.

Stationary as well as mobile cranes help to move cargo from one location to another easily. Generally, cranes are counterbalanced to prevent them from toppling forward with the weight being lifted. Some of them have projecting arms or legs that can be planted firmly to the ground to help maintain stability and distribute weight evenly.

Here, we will focus on cranes that are used in seaports to lift heavy objects such as boxes, machinery, automobiles, and shipping containers.

How are Shipping Containers Loaded and Unloaded?

Cranes play a very vital role when it comes to lifting and stacking heavy objects in the port yard. They are also used to load heavy objects onto a ship.

If we take a gantry crane that is more common in seaports, it has a main supporting framework called the gantry, a boom or a long arm that goes over the ship with a spreader and a cabin suspended over the main framework from where the operator controls the crane. Here, the spreader is a movable clasp that is used to grip and lift cargo containers from and onto a ship.

Mobile cranes have trolleys that move on tracks along the quayside. There are rubber-tired gantry cranes as well. Containers are lifted from the ship and placed on truck beds or on the ground for reach stackers or forklift trucks to move them to their designated area. Port cranes are generally designed to lift weights ranging from 40 to 120 metric tons.

A mechanism called ‘spreader’ is used to attach and lock onto the four corners of a shipping container to lift it for loading or unloading. It locks onto the corner castings of a container using a twist lock mechanism.

Spreaders are designed to lift 20’, 40’, or 45’ containers. A single spreader can lift these containers separately or 2×20’ containers together. Double spreaders can lift single containers, 2×40’ or 45’, or 4×20’ containers in one move. Spreaders are used in different types of cranes to handle shipping containers.

A crane may be diesel-powered or powered by electricity. However, most modern cranes are electric-powered. Separate high-powered motors are used to move the boom, gantry, trolley, and hoisting mechanism.

The cranes used in seaports are generally classified as quay cranes and yard cranes. As their names suggest, quay cranes operate by the quayside, while yard cranes are found in the inner yards of the port.

Quay Cranes

When cargo ships berth along the quayside, large cranes are used to lift shipping containers and other cargo from these ships to shore or from shore to the ship (unloading and loading). The cranes used for this are generally called quay cranes. They are also referred to as Ship-to-Shore or Shore-to-Ship (STS) cranes, as the case may be.

Modern giant STS cranes are mostly classified based on their container lifting capacity from large ships that pass through the Panama Canal or otherwise.

Low-profile STS cranes are generally used in ports and terminals that are located close to airports. They have low, fixed booms. High-profile cranes have booms that can be lifted for ships to berth or, once they are fully loaded, to allow them to pass easily.

Let us look at some of the main quay cranes here.

Panamax cranes

Panamax cranes are used to lift or load containers onto ships large enough to sail through the Panama Canal. The booms of most such cranes can extend their reach up to 30 meters and lift to a height of about 38 meters.

They can lift a weight of about 50 – 65 tons, depending on whether it is a single or a double lift. With lifting speeds that can reach up to 125 meters per minute and a trolley speed of about 180 meters per minute, Panamax cranes are quite fast, too.

Post Panamax cranes

Post-Panamax cranes are used to load and unload containers from large ships, those usually too large to pass through the Panama Canal. Naturally, they are of higher capacity and have a horizontal reach of up to 45 meters and a lifting height of about 35 meters.

Like their Panamax counterparts, they can lift a weight of about 50 tons in a single lift and up to 65 tons in a double lift. Their lifting speed can reach up to 150 meters per minute. The trolley speed of Post Panamax cranes can reach up to 210 meters per minute.

Super Post-Panamax Cranes

With increasing global cargo traffic and as cargo vessels get larger and larger, the port cranes, too, have to keep up with these increasing loads. Ports compete with each other to attract cargo traffic and thereby increase their revenues. Under such a scenario, they cannot afford to have delays or cargo pile up. They should always be equipped to operate better and faster to keep up with competition.

Super Post-Panamax cranes that are used to load and unload shipping containers from very large cargo vessels have a reach of about 50 meters and lift to a height of about 40 meters. Their lifting speed is up to 175 meters per minute, while the trolley speed can reach up to 240 meters per minute.

Bulk Handling Cranes

The general feature of bulk handling cranes is that they have two buckets or grips that can grab bulk cargo, such as coal, mineral ores, grains, etc., for loading and unloading. The grabbing mechanisms used in such cranes are designed to suit handling specific products and conditions.

Gantry Cranes

Fixed gantry cranes generally straddle over a workspace – a space where shipping containers or other types of cargo are positioned for lifting and moving. Mobile gantry cranes that move on tracks or wheels are positioned to straddle over objects that must be lifted and moved.

Floating Cranes

These are large cranes fixed on floating platforms for loading and unloading containers from cargo vessels. These floating platforms are positioned by the side of a ship and used to lift heavy objects.

Tower Cranes

Tower cranes consist of a fixed base, a perpendicular mast, and a boom that rests on a rotating unit. Counterweights are used to balance the boom. The crane operator’s trolley usually rests on the boom from which he controls the crane. A hoist winch and a hook that moves along the boom are used to raise and lower the load.

Yard Cranes

Cranes that are used to move shipping containers and other cargo within a port’s yards are called yard cranes. They are used to move laden or empty containers onto trailers for overland transport or to the quayside for loading on board a cargo vessel. Different types of yard cranes are used to stack containers in the port yard.

Reach Stackers and Container Forklifts

Reach stackers and container forklifts are container handling machines used generally to rearrange or stack containers in a yard. They are also used to load or unload containers from trucks or rail cars.

These stackers and forklifts generally consist of a telescopic or retractable boom that is controlled hydraulically and mounted on a vehicle. A spreader at the tip of the boom is used to attach to the container for lifting or lowering.

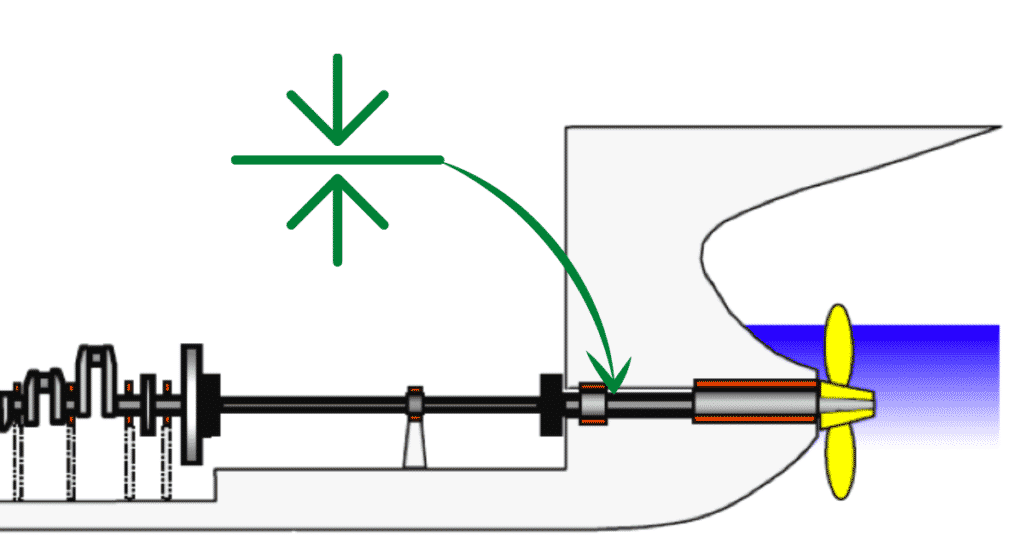

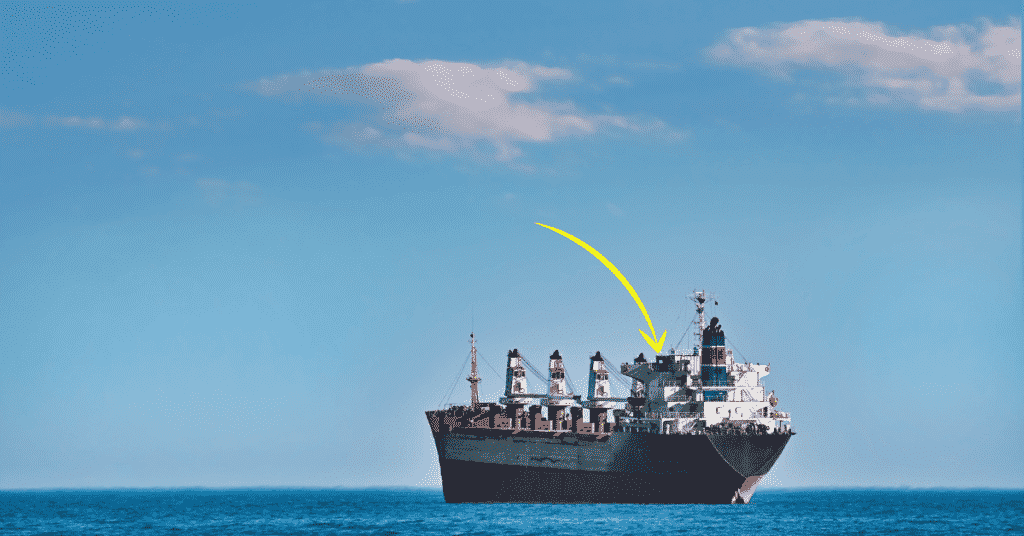

Deck Cranes

Some small ships have deck cranes to lift and lower containers from and to the shore. This comes in handy at ports where cranes are not readily available or when the number of containers is less.

Modern cranes are designed for maximum speed and efficiency. They are used to complete loading and unloading within the shortest possible time, taking into consideration the safety of operating staff as well as infrastructure.

Multiple cranes may be employed to complete loading or unloading containers from a cargo ship within a stipulated time. Trained port crane operators are key to achieving this.

European crane makers are the leaders in port crane manufacture. Liebherr, the German-Swiss giant, Kone, and Kalmar – both based in Finland, are some of the major port crane manufacturers.

You might also like to read-

- What are Telescopic Cranes?

- Port Gantry Cranes: A General Overview

- 6 Largest Gantry Cranes In The World

- What is a Crane Vessel?

Disclaimer: The authors’ views expressed in this article do not necessarily reflect the views of Marine Insight. Data and charts, if used in the article, have been sourced from available information and have not been authenticated by any statutory authority. The author and Marine Insight do not claim it to be accurate nor accept any responsibility for the same. The views constitute only the opinions and do not constitute any guidelines or recommendations on any course of action to be followed by the reader

The article or images cannot be reproduced, copied, shared or used in any form without the permission of the author and Marine Insight.

Do you have info to share with us ? Suggest a correction

About Author

Hari Menon is a Freelance writer with close to 20 years of professional experience in Logistics, Warehousing, Supply chain, and Contracts administration. An avid fitness freak, and bibliophile, he loves travelling too.

Latest Naval Arch Articles You Would Like:

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

Web Stories