5 Biggest FPSOs in the World

Floating Production Storage and Offloading (FPSO) Vessels are invaluable for the offshore oil and gas industry, given their many advantages over traditional offshore oil platforms.

FPSOs are positioned close to an offshore oil field. Using FPSOs over pipelines means that the FPSO Vessel can be moved to another place when an oil field has been exhausted.

FPSOs are built to withstand the harshest conditions and the deepest waters. They can also continually operate for around 20 years and more, proving cost-effective.

Fluids are collected from subsea reservoirs via pipes and then separated into natural gas, crude oil, water, and impurities in the production facilities located on the FPSOs. Crude oil is kept in tanks and loaded into shuttle tankers for distribution or additional refining.

There is an increased demand for new and converted FPSOs, mainly due to the decreasing rate of new onshore oil discoveries and technological improvements that have enabled deepwater oil exploration in unprecedented depths.

FPSOs prove helpful in offshore oil regions that lack a pipeline infrastructure. They are vital in remote areas where building a pipeline network may not be possible due to costs or other reasons.

Today, more than 270 vessels are deployed as oil FPSOs globally.

However, in this article, we will look at the 5 Biggest FPSOs, their functioning and the engineering that makes them the best among the rest.

1. Egina FPSO

TotalEnergies Egina FPSO is the world’s biggest floating production, storage, and offloading vessel by capacity. It is situated in the Egina oil field, around 130 km off the Nigerian Coast, at a depth of over 1500 m.

It is said to be Total’s most ambitious ultra-deep offshore project, which also aims to boost Nigeria’s industrial development and increase its oil production.

The Egina Oil Field was discovered in 2003 and covers an area of approximately 500 square miles. It lies 200 km offshore from Harcourt Port at water depths between 1400 and 1700 m.

According to estimates, the field has 550 million barrels of oil. Approval for developing it was given in 2016, and TotalEnergies started production from the Egina FPSO in 2018.

TotalEnergies operates it and has a 24% stake in partnership with CNOOC, NNPC, Sapetro and Petrobras.

Egina FPSO has a 100-m flare boom and an oil offloading terminal. It is designed to hold 2.3 million barrels of oil and connects to 44 subsea wells at a depth of 1600 m, producing 208,000 barrels of oil every day.

It is also linked to a subsea production system that includes risers, 52 km of oil and water injection flowlines, 20 km of gas pipelines, 12 jumpers, and 80 km of subsea manifolds.

The FPSO weighs around 220,000 metric tonnes and is 330 m long and 60 m broad, making it TotalEnergies’ biggest-ever FPSO. Egina’s topside modules have a gross dry weight of 47,500 tonnes and comfortably accommodate 200 working professionals.

Egina FPSO was built by Samsung Heavy Industries and local contractors in a specially constructed shipyard in Nigeria. Six of the 18 modules were constructed in Africa and integrated locally, the first time such a complicated project was assembled in Africa.

TotalEnergies is continuously innovating Egina FPSO to meet the project’s challenges. For instance, the Vclay subsea production system provides more detailed data and a more accurate understanding of the reservoir and the positions of the wells.

Also, this project has enhanced Nigeria’s infrastructure. A 500 m long dock was built to assemble Egina, which will be used for other projects once it has served this purpose.

Today, Egina is responsible for around 10% of Nigeria’s total oil production, which has allowed Africa to host one of the world’s largest oil and gas projects.

2. Turritella FPSO

This Shell’s FPSO is positioned in the Stones field, an offshore oil and gas project in the U.S Gulf of Mexico. Turritella was designed specially for this field, which was discovered in 2005 and which Shell planned to develop in 2013.

The Turritella FPSO reached the Gulf of Mexico in 2016 and began operations from two subsea wells. Six were added later, along with a multi-phase system to pump oil and gas from the seabed to the FPSO.

At its maximum capacity, it can produce around 50,000 barrels of oil daily. Turritella FPSO functions in a 2900 m water depth, making it the deepest FPSO and the world’s deepest oil and gas production facility of any type.

The Stones Field covers 8 blocks of the lower tertiary geologic trend, and the reservoirs lie approximately 7077 m below sea level. The field is considered to have over 2 billion barrels of oil equivalent.

SBM Offshore constructed the Turritella FPSO in Singapore. It was the first FPSO for Shell and SBM Offshore to be installed in the Gulf of Mexico.

The project was difficult to implement and fraught with many challenges, such as installing and operating subsea infrastructure and equipment at substantial depths. The FPSO also had to face the harsh weather of the Gulf of Mexico, which is known for its hurricanes and violent storms.

Turritella FPSO was built with these hurdles in mind. So it was fitted with the biggest disconnectable buoy in the world to enable it to move away in case of violent hurricanes and to connect later, allowing production to resume as quickly as possible.

It also pioneered using an in-line Mooring Connector, allowing it to readjust every mooring line tension without impacting any installed device. This innovation is now found in several other vessels.

It was also the first to employ Steel Lazy Wave Risers with a disconnectable buoy, which enables the FPSO to maintain stability by absorbing the impact of massive waves, increasing production at extreme water depths.

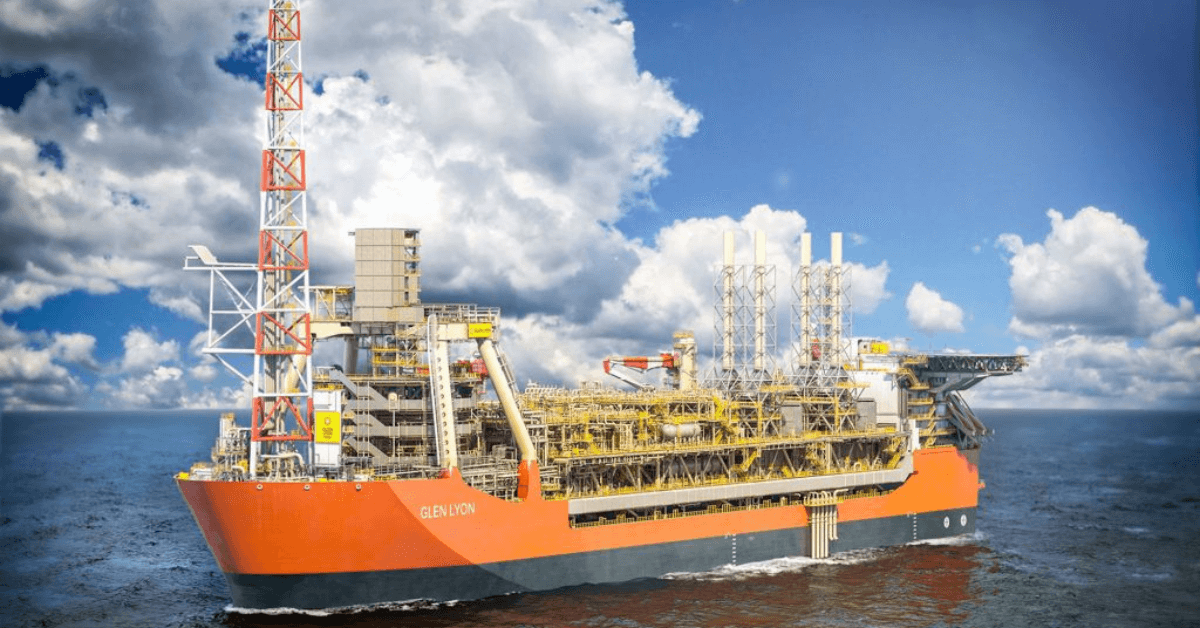

3. Glen Lyon FPSO

BP’s Glen Lyon FPSO can store 800,000 barrels of oil and process and export 130,000 barrels of oil every day. It is also the largest harsh-water FPSO vessel in the world, specially built for BP’s redeveloped Quad 204 Project.

It involves extending the lifespan of the Schiehallion and nearby Loyal fields in the North Sea, located 175 km west of the Shetland Islands.

The fields had produced about 400 million barrels in 15 years, beginning in 1998. Also, the earlier Schiehallion FPSO had to be replaced with a much more technologically advanced counterpart since the operator believed more could be extracted from the oil fields.

The Quad 204 Project aims to extend the field’s production life beyond 2035 and extract around 450 million barrels more.

Glen Lyon was constructed by Hyundai Heavy Industries in South Korea and towed using tugs to Norway and then to its destination, the North Sea. It is 270 m long and 52 m broad, weighing 100,000 tonnes, and can easily accommodate 140 people.

It is built for the rough North Sea conditions and has superior seakeeping and long-term processing capacity. It is anchored to the seabed through a turret mooring system and 20 lines, which run almost a mile long.

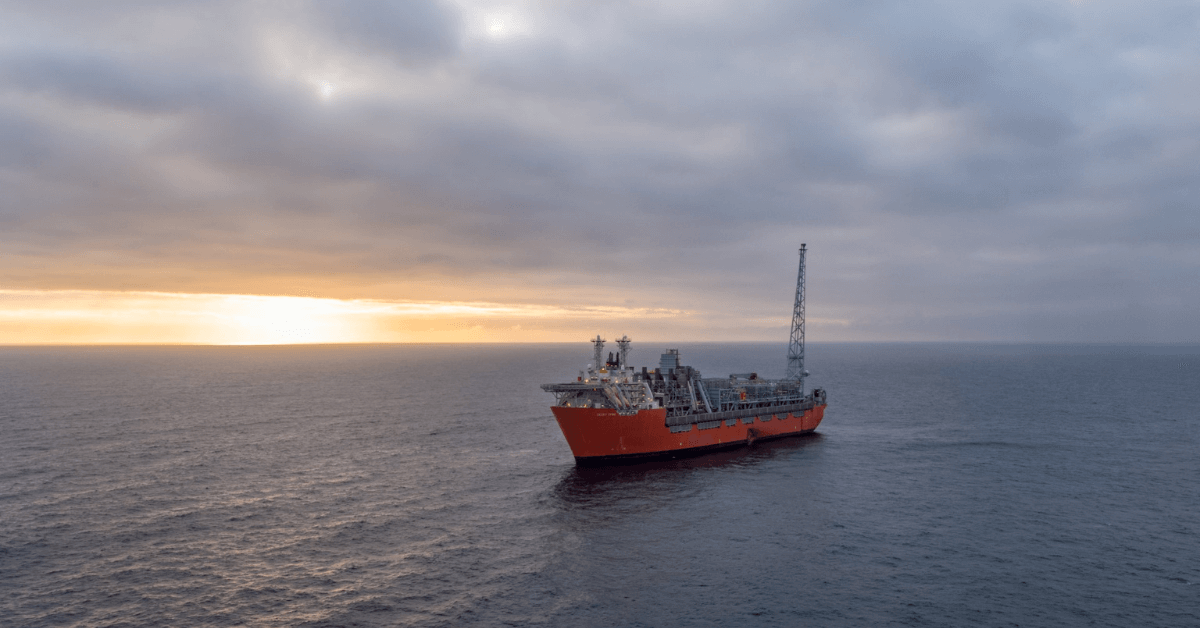

4. Skarv FPSO

Aker BP’s Skarv is yet another massive floating facility with one of the largest offshore gas processing plants where gas is processed before it is sent to the Karsto plant in a more than 800 km long pipeline. Oil from the FPSO is offloaded on tankers.

Skarv Field was found in 1998 in the Norwegian Sea, 50 km south of the Arctic Circle. Construction began in 2008 on the Skarv FPSO to produce gas from the subsea wells. Like Glen Lyon, Skarv has been designed to operate in harsh conditions at water depths of 350 to 450 m.

The main construction took place in Korea, including the 49,000-tonne hull, which measures 295 m long and 51 m broad. A production module weighing 18,000 tonnes was also built, with a production capacity of 85,000 barrels per day, 19 million sm3/d. Skarv FPSO has a storage capacity of approximately 875,000 barrels.

Its turret, constructed in Singapore, weighs 7,500 tonnes. It is 77.4 m high, and its flare tower is 154.6 m above the base of the hull.

The Skarv field began operating in 2012, and the FPSO was connected to 12 production wells, four injection wells, and five subsea templates. According to estimates, the field’s production life is 25 years.

5. Arco Ardjuna FPSO

Arco Ardjuna FPSO was built in 1973, which makes it over 45 years old. Yet it is still operational in the Java Sea. It was designed at a time when FPSOs were not as common as they are now.

The FPSO was built for the Ardjuna Oil Field in the West Java Sea, 95 km from Jakarta, Indonesia. It spand 8300 km2 and has 314 producing wells.

Initially, ARCO operated it, but later, BP West Java came into the picture. Today, Arco Ardjuna is operated by the government-owned Oil and Gas Company Pertamina.

The FPSO was built in Japan at the MHI Nagasaki Shipyard & Engine Works.

It weighed 53,734 tonnes, making it one of the biggest ships in the world when it was being constructed. Given its age, the fact that it still operates today is no less than an achievement. It was recently linked to pipelines tied to Pertamina’s KLB Pavilion in YY field off the Indonesian coast.

Conclusion

With each passing year, we witness the emergence of new technologies in the maritime sector. Ships are getting bigger, better, and more advanced, and so are FPSO Vessels, whose existence is vital for the offshore oil and gas sector. FPSO vessels offer many advantages and are cost-effective since they can be moved to another location.

They operate in the harshest weather conditions, from the Gulf of Mexico to the North Sea and the Norwegian Sea. They are marvels of engineering and testaments to human ingenuity.

In the rapidly expanding global energy landscape, the biggest FPSO vessels help meet the needs of the global market and help move the offshore oil and gas industry towards a greener and more efficient future.

You might also like to read-

- What is FPSO (Floating Production Storage and Offloading) System?

- Munin – The Award Winning FPSO (Floating, Production, Storage and Offloading) Ship

- Maersk’s Floating, Production, Storage and Offloading Systems (FPSOs): The Fantastic Four

- The LNG Supply Chain Explained

- 14 Types of Ships with Dynamic Positioning System

Disclaimer: The author’s views expressed in this article do not necessarily reflect the views of Marine Insight. Data and charts, if used in the article, have been sourced from available information and have not been authenticated by any statutory authority. The author and Marine Insight do not claim it to be accurate nor accept any responsibility for the same. The views constitute only the opinions and do not constitute any guidelines or recommendations on any course of action to be followed by the reader.

The article or images cannot be reproduced, copied, shared or used in any form without the permission of the author and Marine Insight.

Do you have info to share with us ? Suggest a correction

Latest Maritime Knowledge Articles You Would Like:

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

Web Stories

About Author

Zahra is an alumna of Miranda House, University of Delhi. She is an avid writer, possessing immaculate research and editing skills. Author of several academic papers, she has also worked as a freelance writer, producing many technical, creative and marketing pieces. A true aesthete at heart, she loves books a little more than anything else.